Colossal Load Marks Key Project Milestone

On a blustery spring morning in 2023, ceremonial shovels were dug into the dirt, symbolizing the groundbreaking of a significant International Paper capital project, and one of the largest projects in Cedar River Mill’s history. Now, a year later, the project to build two natural gas power boilers is full steam ahead.

The $103 million investment began as many do with plenty of earth moving, underground pipe lament and prep work. With the groundwork complete, the next step was to lay the foundation.

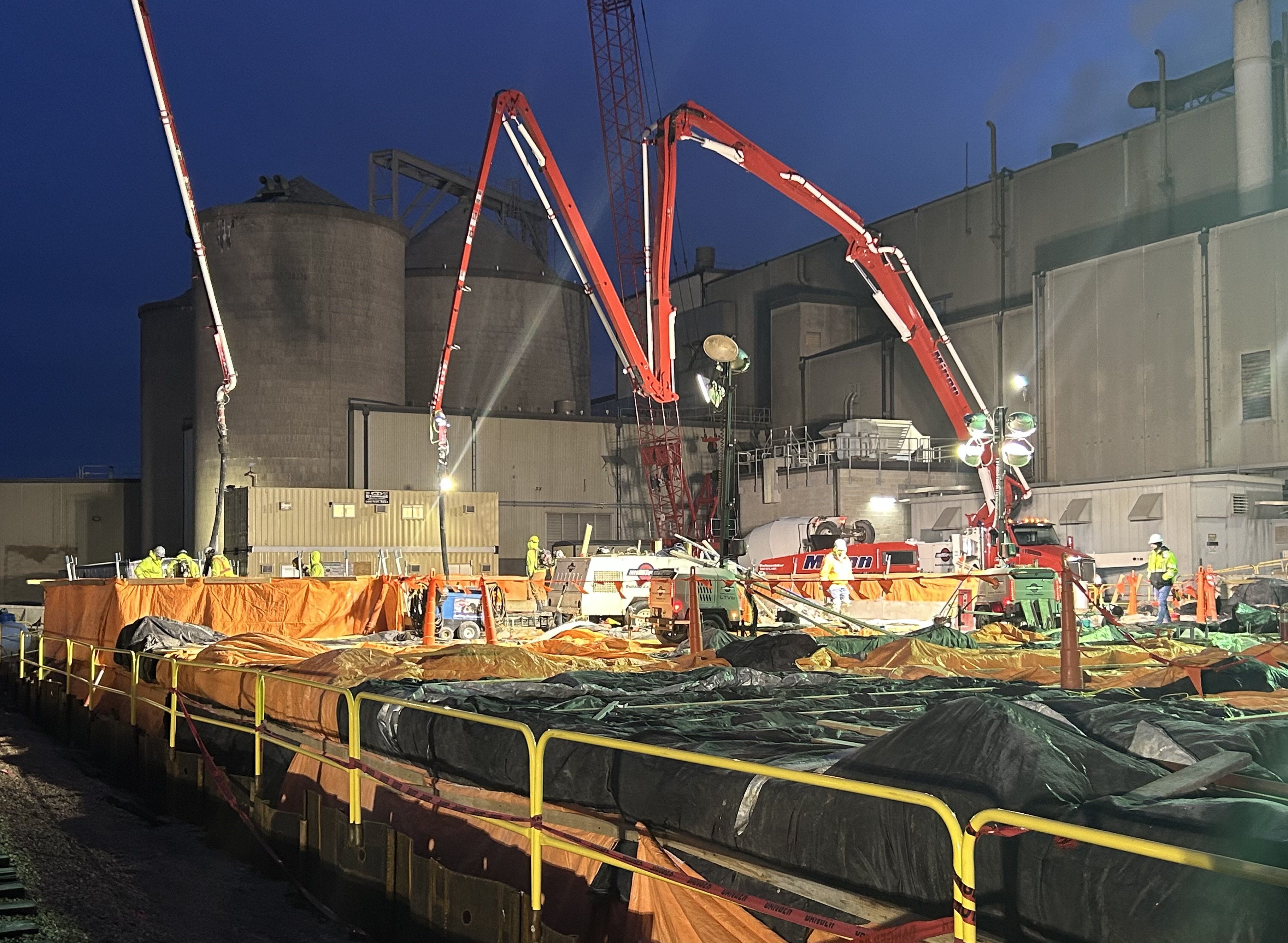

Foundations and Support

Over 11 weeks, about 5,350 cubic yards of concrete was poured, creating the six-and-a-half-foot thick foundation for the future boilers and water treatment. Approximately 535 trucks brought in the cement over five separate pour dates.

The feat of this part of the project was massive. To ship something that is that heavy over the road, takes a large amount of engineering.

As you can imagine, the magnitude of these pours came with several planning obstacles: logistics, active rail, pump truck placement and weather, to name a few. “All of this was done within a constrained project space,” said project team member Pat Naughton.

“And we had to do it while keeping quality and the safety of all involved at top of mind,” added Taylor Walkner, another team member. “Collaboration and engagement was one of the biggest factors in making this portion of the project successful,” he said.

Adding to the complexity were Iowa’s chilling winter temperatures, which required a special concrete thermal control plan and 24/7 monitoring.

This was only the beginning.

Delivering "Five Elephants”

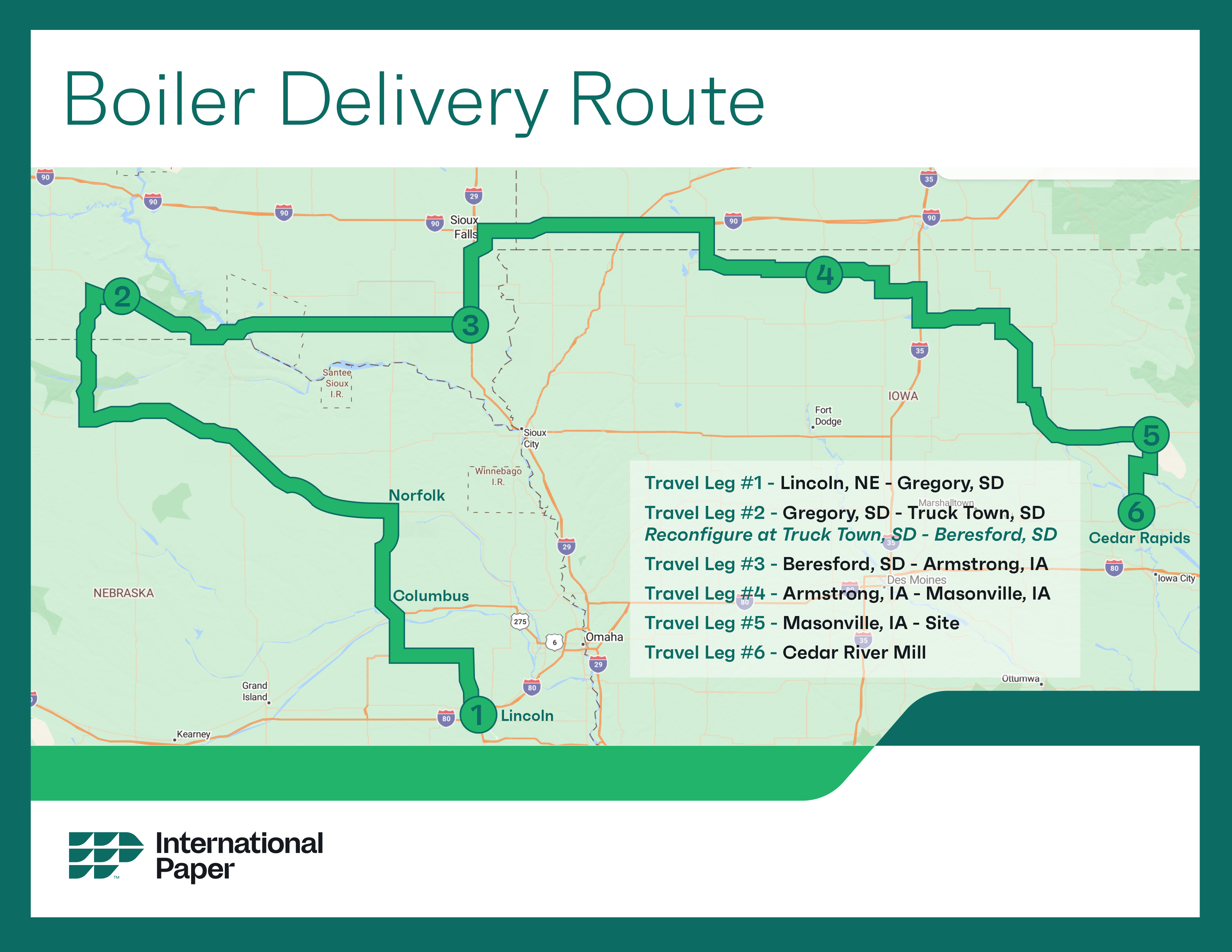

Built in Lincoln, Nebraska, the two natural gas boilers were the largest fully assembled boilers that could be transported via heavy hauler.

Including the 24-feet wide, 17-feet tall boiler, the massive hauling unit totaled 220 feet and weighed approx. 620,000 pounds. Due to the magnitude of the colossal load, extensive travel requirements were in place to ensure the safety of all involved. Permits were needed in every county and city they planned to travel through. In total, the hauler would need to travel 700 miles through three states, twice over, a journey that required a police escort and lifted power lines.

“The feat of this part of the project was massive. To ship something that is that heavy over the road, takes a large amount of engineering. It was eye-opening once you start diving into the details of how much coordination is required to make sure it’s going to be safe for all parties,” said Tony Cleves, project manager.

After a 12-day journey, the first boiler arrived at the mill on March 19. The team then did it all again, and the second boiler was delivered on April 5.

Moving into Position

Once onsite, the team disassembled the transport, rotated the boilers and prepared them for the short journey to the project site.

This is a once in a lifetime opportunity. Not just for the project team, but for the mill as a whole.

An 80-wheeled goldhofer – a hydraulic modular platform trailer driven by remote control and used for heavy transportation – moved the boilers to the project grounds. Travelling at walking speed, it took less than 30 minutes for crews to move the boilers, watching carefully to ensure levelness of the 24-foot-tall load. A crane was used to lift and lower them into their final resting places.

Over the past year, the mill has been buzzing about this project. “This is a once in a lifetime opportunity. Not just for the project team, but for the mill as a whole,” said Tony. “Many of the mill employees are on the project team and we’ve incorporated a large number of team members into the project overall. People are informed, they are involved, and that tends to lead to more excitement.”

Looking to the Future

Once this project is complete at the end of 2025, the mill’s emissions will be reduced by approximately 25% as a result of the replacement of the coal-based steam currently used. This will contribute to our Vision 2030 target of reducing our enterprise greenhouse gas emissions by 35% by year 2030. You can read more about it in our Sustainability Report.

"The main building structural steel will start being erected in June, said Tony. “We have a lot more to go, but this is a great milestone to have behind us.”