What a Mess: Open Container, Waste Paper Blows Everywhere

This direct marketing print fulfillment client faces fast turnaround demands for its customers’ quick-response mailing services. With a national roster of clients serving healthcare, finance, insurance, utilities, and nonprofit segments, the printing firm speeds response to its clients’ customers and prospects by printing product literature and other materials in advance, holding them in inventory so materials are ready to ship same-day, immediately upon request.

Batch runs of flyers, booklets, and product pages are stored on shelves and in preprinted rolls to provide this just-in-time response. But inevitably, product changes and marketing design updates meant changes in print materials held in stock. Using its battery of digital, inkjet, and commercial printing and finishing equipment, this mailing firm doesn’t miss a beat, rapidly replacing print materials with updated versions for its customers.

Logo and design changes mean old materials must be discarded, and that creates a steady stream of waste paper of all types—envelopes, flyers, booklets, paper rolls, old corrugated cardboard. This commercial printer contracted with a supplier for paper waste removal services.

Then, their commercial recycling services supplier moved and was unable to make frequent pickups. Their existing supplier’s “solution” was a 30-yard open-top container, left in the parking lot, and the printer was told to call when it was full.

.

The recycling services provider’s plan wasn’t working out. During what now became a lengthy gap between pickups, waste paper in the open drop box container was exposed to the elements. At the mercy of rain, dust, and even birds, wind gusts began scattering the paper around the plant parking lot. “It was during our peak printing season,” the client says, “because this 30-yard container didn’t have a lid, all our paper scrap was getting blown out of this container all over the back of our parking lot.”

With this mess on its hands, the printer sought bids for a new recycling services provider. In August, Amy Bowes, International Paper’s Recycling Services Representative, fielded an inquiry that arrived through the IP website. She visited the site, met with the client, and offered improved solutions based on that discovery meeting.

“This client services customers like insurance companies sending out open enrollment documents,” says Bowes. “Or medical facilities, sending out customized pieces regarding their services. They print a lot of masters and a lot of warehoused documents, anything that you can think of as it relates to direct mail printing.” For an insurance company customer, for example, “They will print a bunch of open enrollment documents, ship them out per the schedule, and then keep everything else on the shelf until that next group is ready to receive their printed materials.”

By October, International Paper was selected as the recycling services provider by the client, providing a broader range of services than the previous supplier, according to Bowes. “Now we help them recycle more types of waste, such as paper trimmings from the pressroom, used corrugated boxes, and remainders of printing paper rolls, three feet in diameter used on offset presses.”

.

Choosing IP for recycling was an easy call. For one, IP was able to make regular—every Tuesday—and far more frequent pickups than the old supplier.

Although IP’s Richmond recycling facility was a little more distant than two other bidders, there were distinct advantages that appealed to the client. Tailoring the solution to the client’s needs, IP worked with the print client to establish a waste paper sorting process: large corrugated gaylord boxes on pallets receive printed waste paper graded by type: white paper, mixed white paper, and old corrugated cardboard. “The gaylords are very thick and durable; many of our clients use them to collect fiber-based materials for recycling. Then we back a 53-foot International Paper trailer into their loading dock,” explains Bowes. “As they fill up, the gaylords are shuttled by a forklift onto it.” No longer does the client see paper blowing in the wind.

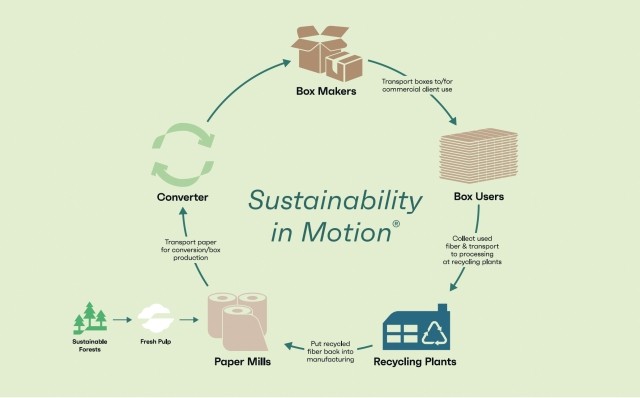

IP also provided a greener process for the client. The sorted gaylords are weighed and graded by type, and IP documents the volume of paper and cardboard destined for its mills, to be converted back into packaging and other paper products— a truly circular approach that is the most sustainable method of handling waste paper.

.

“When they were collecting recyclables in that big open-top collection, the other recycling services provider wasn’t even separating it out into paper grades,” Bowes says. “The previous supplier definitely was not providing back any itemized material receipt document like IP now provides.”

And one last advantage IP offered: rebates, based on the value of the sorted waste paper, by grade. White paper, the most desirable for circular recycling, receives the highest rates in rebates, and less desirable waste, like No. 10 window envelopes with cellophane panels, pays less. “Revenue to the client’s business for its waste paper now offsets the hauling service fee,” says Bowes. “Those white paper grades are worth a lot more. Now waste isn’t flying away, and the paper is separated by grade in the gaylords to get better value for the client.”

This sorted waste is taken to IP’s recycling facility in Richmond, VA. “We unload it from the trailer and then take those separated materials and put them in staging bunkers, each one a designated area for a specific paper grade,” Bowes explains. The amount is significant: running about 50 tons per month, all diverted from landfill, and entering a circular recycling process that turns those tons back into boxes and paper products.

“IP has been around for 125 years, and we are truly a full-circle sustainable partner,” says Bowes.

Your Partner for the Future

International Paper’s Sustainability in Motion® offers customized solutions including baling, hauling, and data reporting. These solutions, tailored to each customer location, in many cases include rebates based on the market value of your waste fiber, which IP converts to new packaging products at its many mills. With a potential new revenue stream, IP can bring your circularity efforts to a new level, with recycling services and integrated mills providing full-circle solutions for your business.

International Paper is your recycling partner for the future. We are your best end-to-end, closed-loop sustainability partner. We design custom solutions for businesses of all sizes, with a focus on maximizing your economic and sustainability value at every point. For International Paper, recycling is a culture, not a commodity.

Let International Paper put Sustainability in Motion® for you.

Contact us to get your recycling solution started with a free on-site assessment