Waste Hauling Costs Were Rising Too Fast as Production Jumped

One of the world’s largest providers of integrated electronic components, this global Fortune 500 client’s western U.S. operations center’s services are in high demand for the fastest growing segment of the electronics industry. Its many offerings include design, fabrication, and assembly of printed circuit boards and multilayer backplanes (an electronic “sandwich” of up to 70 layers) for OEMs in the industrial, medical, defense, automotive, communications, and cloud infrastructure markets.

Packaging waste is generated in high volumes from incoming subassemblies and raw materials. In addition, packaging for individual products offered to end users results in even more refuse. To keep operations on track, the manufacturer’s packaging waste must be reliably taken away. Mounting volumes were driving up costs with its current waste hauler.

.

When an online inquiry to International Paper came from the operations manager at the firm’s West Coast electronics component division, IP’s Fremont, CA Plant General Manager, Kuljit Rai, responded and immediately dispatched colleague Raj Madhavan to assess requirements and develop solutions.

“Our current waste hauler is doing a good job,” the operations manager said. “But I really need to show some savings. Can you help me out?” IP specializes in custom recycling solutions for manufacturers across the United States. With recycling plants nationwide, and a transportation network able to meet any demand, IP’s recycling experts are always ready to tailor a plan specific to your needs.

“I met their whole team and saw their whole infrastructure,” said Madhavan. “I said, ‘Look, we could do the same thing for you, but our cost is much less.’ They were using two 30-yard bins, and they were filling up two cardboard bins—almost 4,000 pounds each—three times a week.”

The manager said his facility was paying $10,000 a month for hauling recyclables, and getting no rebate for the value of waste cardboard from its hauler.

Lower Hauling Fees, and a Rebate for Reclaimed Fiber

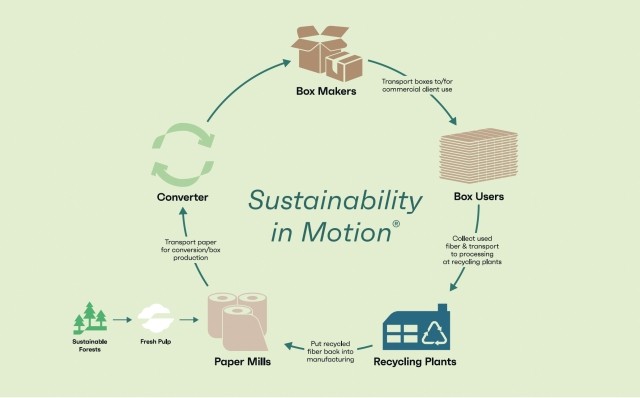

IP was able to provide the electronics manufacturer with speedy, punctual waste hauling services, on the same frequency as the other supplier, and at less cost. Within 10 days from initial contact, IP trucks began to stop by three times a week to pick up waste material. Due to its economies of scale and its efficiency, IP hauls this customer’s container waste for thousands of dollars less each month. In addition, rebates from IP based on the value of the client’s old corrugated container fiber offset their costs even further. By converting its waste into new fiber-based packaging, IP also helps this customer meet its aggressive environmental goal for realizing a 40 percent reduction in greenhouse gas emissions by 2030.

Your Partner for the Future

International Paper’s Sustainability in Motion® offers customized solutions including baling, hauling, and data reporting. These solutions, tailored to each customer location, in many cases include rebates based on the market value of your waste fiber, which IP converts to new packaging products at its many mills. With a potential new revenue stream, IP can bring your circularity efforts to a new level, with recycling services and integrated mills providing full-circle solutions for your business.

International Paper is your recycling partner for the future. We are your best end-to-end, closed-loop sustainability partner. We design custom solutions for businesses of all sizes, with a focus on maximizing your economic and sustainability value at every point. For International Paper, recycling is a culture, not a commodity.

Let International Paper put Sustainability in Motion® for you.

Contact us to get your recycling solution started with a free on-site assessment